PIPE CONVEYOR DESIGN

Pipe conveyors belts are a popular alternative to trough conveying when horizontal curves are very tight, dust emissions are unacceptable, or the inclination angle is steeper than trough belts will allow.

Typical Scope of Work

Our scope of work on pipe conveyors typically mirrors the scope of work we outline for trough conveyors . However, when we are involved in a pipe conveyor, we typically add the following important items to our scope:

- Pipe Conveyor Belt Sample Stiffness Testing

- Pipe Conveyor rolling and un-rolling transition layout drawing

- Pipe Conveyor Overloaded protection panel detail drawings

- Typical pipe idler panel with training idler detail drawings

WHY PARTNER WITH CDI ON YOUR NEXT PIPE CONVEYOR PROJECT?

When you partner with CDI, you benefit from of our decades of experience designing these machines and can execute the project confidently, knowing you will avoid common pipe conveyor issues like excessive rotation and edge damage. Your client will appreciate that you have partnered with the designers of the longest pipe conveyor in the world-- the the 15km Yubei Pipe Conveyor in China.

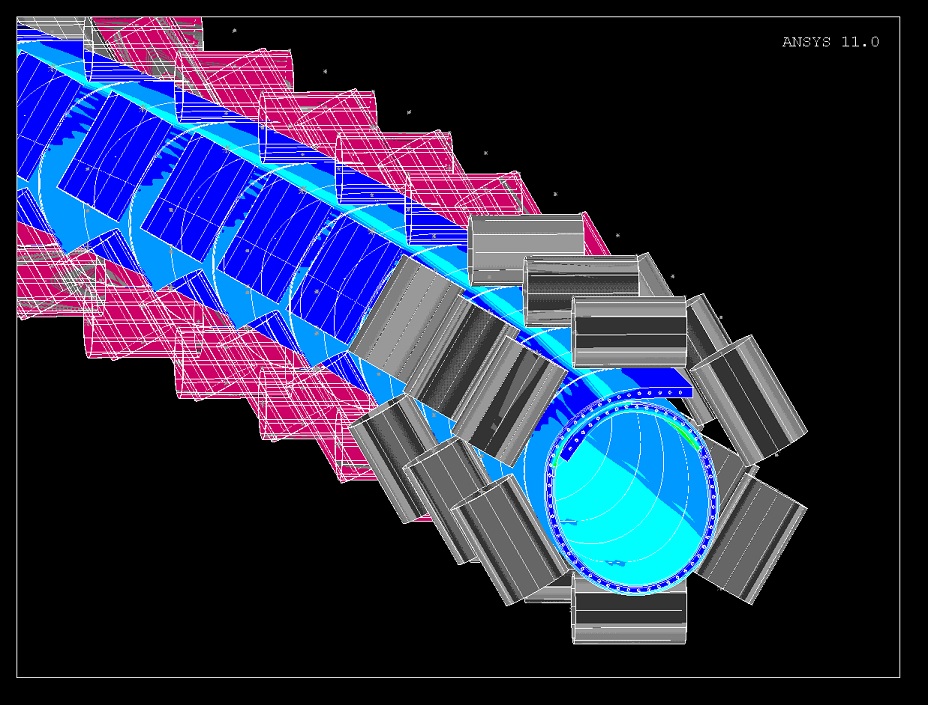

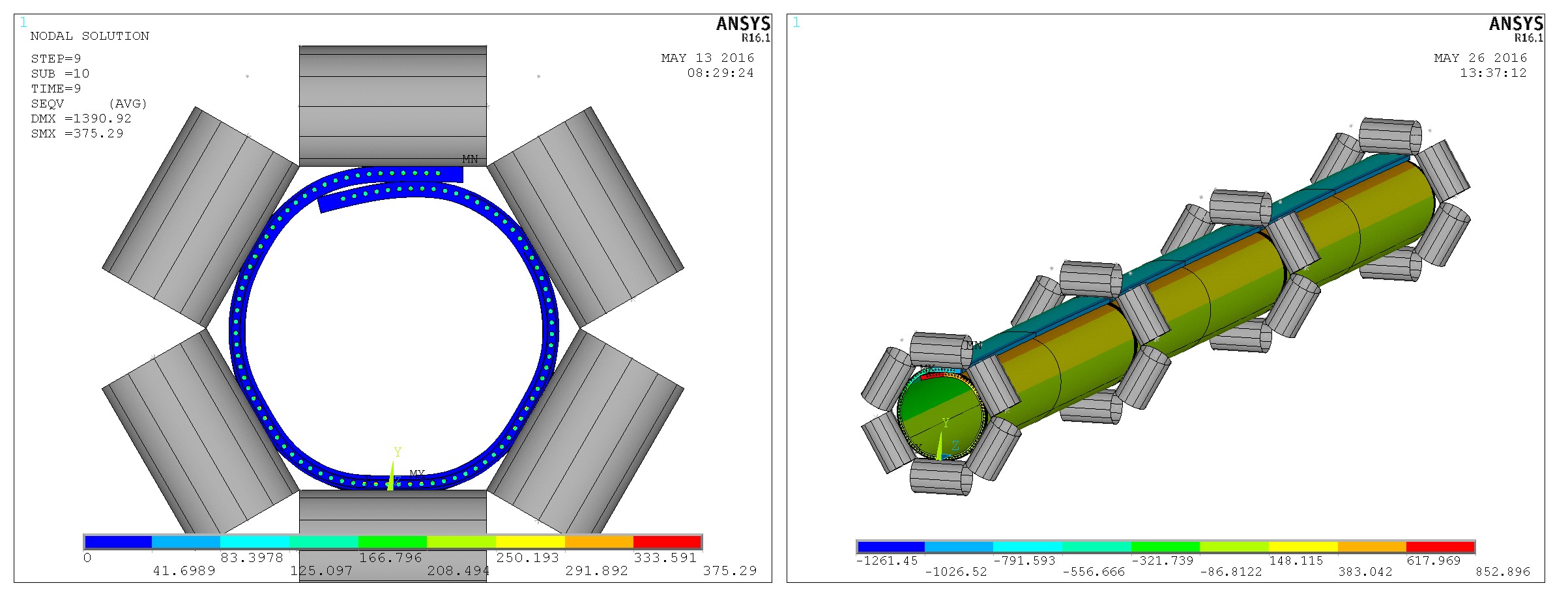

Conveyor Dynamic Inc. (CDI) has developed unique Finite Element Analysis (FEA) pipe conveyor models and sample test procedures that allow us to accurately predict the power consumption more accurately than any other company in the world. We use this model to resolve the most common problems with pipe conveyors: excessive pipe rotation and pipe collapse. We also use it to design need pipe conveyor systems and to provide our clients with belt specifications to ensure that the belt they purchase will perform acceptably. Many of the largest belt manufacturers in the world have hired CDI to assist them with pipe conveyor product development including patented pipe carcass constructions.

PROBLEMS WITH AN EXISTING PIPE CONVEYOR?

Conveyor Dynamics can help! Every year operators from around the world contact us to assist with a failing pipe conveyor. Typically, we can resolve their issue by providing a belt specification and qualifying new belt suppliers for their conveyor but sometimes we need to adjust the transition zones of the belt.